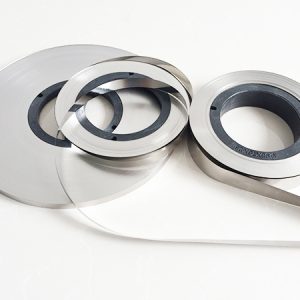

Iron-based Amorphous Alloy Strip

Iron-based amorphous alloys strip is a new type of soft magnetic alloy material, it adopts the international advanced ultra-quenching technology to cool the melted metal at the speed of millions of degrees, forming a thickness of 25-35μm amorphous alloy strip. The atomic arrangement combination with short-range order, long-range disorder characteristics of amorphous alloy structure.

Samples With Cost-Free !!!

- Manufacturer: SHOUKE

- Product Size: Standard or Customized

- Certificates: ISO 9001:2015, RoHS, REACH, SGS

- Transportation: By sea, By air or By train

- Delivery time: Samples: 3~7days; Batches: 7~20 days

Introduction:

Iron-based amorphous alloys strip is a new type of soft magnetic alloy material, it adopts the international advanced ultra-quenching technology to cool the melted metal at the speed of millions of degrees, forming a thickness of 25-35μm amorphous alloy strip. The atomic arrangement combination with short-range order, long-range disorder characteristics of amorphous alloy structure. And it is completely different from traditional alloy materials in the microstructure. Therefore, it has unparalleled excellent characteristics of traditional metal materials in physical properties, chemical properties, mechanical properties and many other aspects. In addition, the manufactoring process is completely different from the traditional metallurgical process, it saved the traditional metallurgical process in casting, forging, annealing, rolling and other processes, which also saved a lot of energy, and pollution-free emissions, amorphous alloy is known as environmental protection, energy saving, efficient new green materials.

Benefits:

1) The iron-based amorphous alloys with High Saturate induction (1.56T) and High magnetic permeability(>10000), which can minimumize the size of components.

2) Amorphous alloys strip with less core loss only has 1/5 core loss of silicon steel, and the core loss can lower as 100w/kg at 10KHz, 500mT, and it reduces the temperature rise very well.

3) The coercive force (Hc) could lower as 5.0A/m, and the efficiency of components could be improved.

4) The saturation magnetostriction close to zero, so it can lower the working noise effectively.

5) The properties of amorphous alloys strip is stable at -50℃~150℃.

Physical Properties:

| Item | Performance |

|---|---|

| Material Grade | 1K101 |

| Material Ingredient | Fe, Si, B |

| Material Thickness | 30±5um |

| Saturate induction Bs(T) | 1.56 |

| Curie temperature Tc(℃) | 415 |

| Crystallization Tx(℃) | 540 |

| Coercivity Hc(A/m) | <4 |

| Hardness(Hv) | 960 |

| Stacking Factor | ﹥84% |

| Magnetostriction (λs) | 27×10 -6 |

| Density ρ(g/cm3) | 7.18 |

| Resistivity δ(μΩ.cm) | 130 |

Specifications:

| Material | Model | Width(mm) | Thickness(um) |

|---|---|---|---|

| Amorphous Alloy Strip | 1K101 | 5 | 26±2 |

| Amorphous Alloy Strip | 1K101 | 6.5 | 26±2 |

| Amorphous Alloy Strip | 1K101 | 8 | 26±2 |

| Amorphous Alloy Strip | 1K101 | 10 | 26±2 |

| Amorphous Alloy Strip | 1K101 | 15 | 26±2 |

| Amorphous Alloy Strip | 1K101 | 20 | 26±2 |

| Amorphous Alloy Strip | 1K101 | 25 | 26±2 |

| Amorphous Alloy Strip | 1K101 | 30 | 26±2 |

| Amorphous Alloy Strip | 1K101 | 35 | 26±2 |

| Amorphous Alloy Strip | 1K101 | 40 | 26±2 |

| Amorphous Alloy Strip | 1K101 | 45 | 26±2 |

| Amorphous Alloy Strip | 1K101 | 50 | 26±2 |

| Amorphous Alloy Strip | 1K101 | 55 | 26±2 |

| Amorphous AlloyStrip | 1K101 | 60 | 26±2 |

| Amorphous Alloy Strip | 1K101 | 65 | 26±2 |

| Amorphous Alloy Strip | 1K101 | 70 | 26±2 |

| Amorphous Alloy Strip | 1K101 | 80 | 26±2 |

Note: We can also customiz the width of amorphous alloy strip according to custom’s requirement.