-

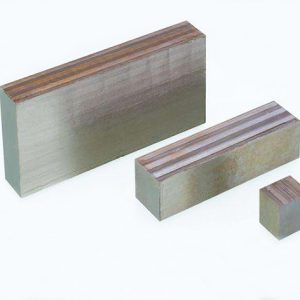

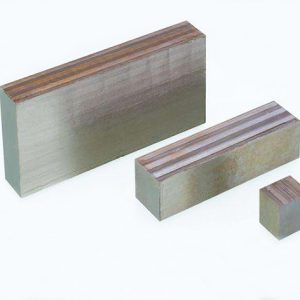

The block core is made by stacking Fe-based amorphous alloy ribbon or lamilations, and the laminnations are banded together by an adhesive rated for a continuous operating temperature of 155°C. The amorphous alloy itself has a higher continuous operating temperature.

-

The PFC cores (Power Factor Correction) with gap is based on the Fe-based amorphous alloys, It has excellent characteristics of constant inductance and anti-DC magnetic bias, and the loss is lower.

-

Fe-based amorphous alloys have excellent magnetic properties, however do not reach the low losses or high permeabilities of nanocrystalline alloys due to the relatively high magnetostriction. The advantages are a higher saturation flux density and lower costs.

-

Compared with traditional silicon steel motors, Amorphous Stator Cores has higher efficiency and lower core loss.The power density of amorphous motors is high, and they are lightweight, small in volume, and can reduce heat.

-

Co-based amorphous alloy strip has the characteristics of high permeability, low coercivity, extremely low loss, good temperature stability, and close to zero magnetostrictive coefficient. Besides, it is not sensitive to mechanical stress and can work in harsh environments for a long time, which greatly improve the stability and reliability of product, especially for transformers and inductors in military power supplies, and replacing permalloy and ferrite.

-

The DC Immune combined Cores be made by amorphous alloys core and nanocrystalline alloys core, which could detect accurately the AC signal, and resist the DC, and it could meets the high precision and linearity requirements.

-

Fe-based Nanocrystalline alloy strip with Fe, Si, Nb, B, Cu ingredients, and the nanocrystalline materials have high saturation magnetic induction, high permeability, low coercivity, low loss and good stability, wear resistance, corrosion resistance and other excellent properties.

-

Fe-based Nanocrystalline Current Transformer has higher magnetic permeability and low loss than traditional magnetic materials, and this current transformer are characterized by high precision and high stability.

-

Fe-based nanocrystalline cores have been used in the high-frequency(100kHz) power transformer, and it has high saturation magnetic induction, low loss, and near-zero magnetostriction, which can reduce the size and weight of components and lower energy consumption.

-

Iron-based amorphous alloys strip is a new type of soft magnetic alloy material, it adopts the international advanced ultra-quenching technology to cool the melted metal at the speed of millions of degrees, forming a thickness of 25-35μm amorphous alloy strip. The atomic arrangement combination with short-range order, long-range disorder characteristics of amorphous alloy structure.

-

Nanocrystalline cores are widely used in common mode inductor applications due to their unique combination of magnetic properties. Nanocrystalline cores feature a very high initial permeability which enables a high attenuation in the low frequency range with only a small number of turns.

-

The Nanocrystalline Alloy Cores with Higher permeability are widely used for Low Voltage, Medium Voltage and High Voltage Current Transformer.

-

Nanocrystalline alloy cores have a combination advantages of silicon steel, permalloy and ferrite, and the working frequency of high frequency inverter power supply is 20 kHz ~ 50 kHz.

-

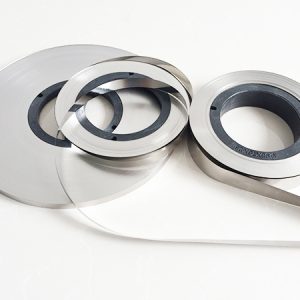

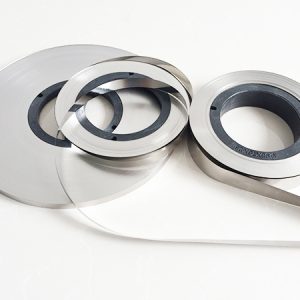

The toroidal split cores is made from the nanocrystalline alloy ribbon/strip, and nanocrystalline cores has lower core losses, high induction and low noise when operating at accoustic frequencies due to the low magnetostriction.