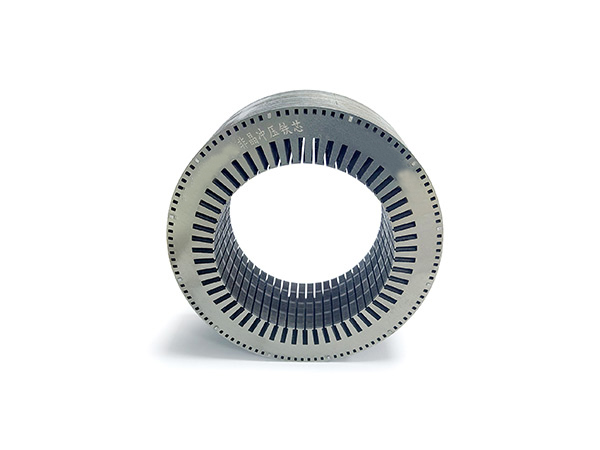

Amorphous Stator Cores of Motor

Compared with traditional silicon steel motors, Amorphous Stator Cores has higher efficiency and lower core loss.The power density of amorphous motors is high, and they are lightweight, small in volume, and can reduce heat.

Samples With Cost-Free !!!

- Manufacturer: SHOUKE

- Product Size: Standard or Customized

- Certificates: ISO 9001:2015, RoHS, REACH, SGS

- Transportation: By sea, By air or By train

- Delivery time: Samples: 3~7days; Batches: 7~20 days

Introduction:

Motors are extremely important power equipment in industrial production and social life. Their power consumption ranks first among various electrical appliances. Global motor power consumption accounts for over 50% of the world’s total power consumption and about 70% of industrial power consumption. Under high-speed and high-frequency conditions, the amorphous motor cores can significantly reduce motor losses and increase efficiency by 3% to 20%.The power density of amorphous motors is high, they are lightweight, small in volume, and can reduce heat.

Compared with traditional silicon steel motors, Amorphous Stator Cores have two obvious advantages.Firstly, the resistivity of amorphous materials is three times that of silicon steel sheets, and their thickness is only 1/10 of that of silicon steel sheets. Eddy current losses are significantly lower than those of silicon steel sheets. Secondly, the operating efficiency of amorphous motors is as high as 98.5%, thus solving the problem of excessive volume caused by the need to equip cooling devices in traditional high-frequency devices. They play an important role in electric drive, high-speed spindles, aviation generators, and military fields.

Features:

- Lower core loss than silicon steel motors.

- High motor efficiency

- Corrosion resistance and toughness

Applications:

-

- Electric vehicles

- High speed motors

- Railway transportation equipment

- CNC

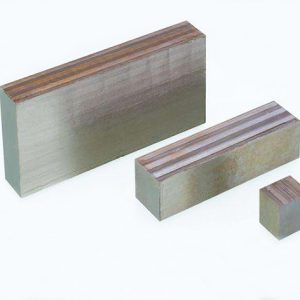

Specifications:

We produce the amorphous stator cores according to customer’s technical drawing.